.

Back when I was young and the world was gay... or maybe that should be the other way ‘round... No, that sounds even worse. Lemme start over.

Back when I was a kid in Modesto, California there was a delightfully perverse young lady who could suck a golf ball through a fifty foot garden hose. She occupies a special place among my memories because she taught me a lot about auto mechanics. Or rather, she caused me to learn a lot about auto mechanics. She lurched into Hendy's Drive-In in her 1937 Ford tudor, said it was running like shit and offered to demonstrate her remarkable talent for anyone who could fix it, pronto. The car immediately vanished under a dog-pile of hot-rodders oozing testosterone. Half an hour later the car was still there. It would idle okay but began bucking and wheezing whenever the throttle was touched. The hot-rodders had vanished; the prize unwon.

I strolled over as she was latching the hood (it folded up from either side), nudged her aside, pulled the air cleaner, played the choke & throttle together to get the revs up to about 2500 rpm, then mashed my hand over the throat of the carb, which just about did to me what she could do to a golf ball.

Didn't help. So I did it again. The third time I gave it the Po' Boy Carb Clean, it cleared whatever had been blocking the high-speed circuit, settled down and ran like a top. I put the air cleaner back on, latched the hood and strolled away, the epitome of Mr. Cool, right down to my blue suede shoes.

Actually, it was pure dumb luck. The hot-rodders were convinced she had a problem with her ignition and gave the car a quick tune-up while I watched. By the time they were done it was pretty obvious the problem had to do with a lack of fuel at high speed, which everyone assumed was due to a bad fuel pump or a dirty carb and since neither could be repaired pronto, they gave up.

Truth is, I didn't know what marvelous things occurred when you revved an engine then shut off the air with your hand. But over at the VW dealership where I worked I'd seen one of the mechanics do it for a beetle with the same symptoms and it seemed worth a shot. It wasn't until later, when the grateful young lady was fulfilling her promise, that I experienced a suction-related epiphany.

Manifold Pressure That Isn't

Your engine is an air pump, right? (Auto Shop 101. Which happens to be wrong but there it is.) Rev the engine, it's gotta suck some air. Close the throttle, the engine can pull a pretty good vacuum before it slows down. If you can somehow extend that suction to above the throttle plate -- to include the entire carburetor -- it will occasionally clear a clogged jet or bleeder port. To accomplish that, simply clap your hand over the inlet to the carb.

The suction is the result of the pistons descending in their cylinders with the intake valve open during what is called, oddly enough, the Intake Cycle. (For your Pop Quiz, during which cycle does the piston descend with the intake valve CLOSED?). The amount of suction is always greatest when the throttle is closed or nearly so, which occurs at idle or whenever you suddenly lift your foot from the accelerator.

We tend to think of the suction occurring only in the intake manifold; that its only role in life is to suck some gas out of the carb. We tend to forget that the vacuum is present everywhere in the system, from the top of the carb right through to the top of the piston down inside the cylinder.

It's the presence of that vacuum that causes oil to be drawn into the combustion chamber. If your rings and valve guides are in good shape the amount of oil drawn into the chamber is small but there's always some; if your rings or valve guides are worn - and if the guides are not fitted with seals -- the suction can pull a copious amount of oil into the cylinder. That's what causes you to blow white smoke out the tail pipe, fail your smog test and stink up the neighborhood.

(Didja notice the or? )

Rings or guides. We tend to say ‘valves' instead of guides but in fact, the valve's stem is steel whereas the guide is putty-soft aluminum-phosphor-bronze. After thirty thousand miles we can expect the valve's stem to be a little bit worn but most of the wear appears in the softer guides. (See 'Wiggle-Wiggle.' Or the factory service manual. The 'wiggle' test is a standard procedure for all OHV engines.)

With aircooled Volkswagens it's important to make the distinction between valve guide wear and piston ring wear because the guides wear-out about four times faster than the rings. Fail your smog test because of elevated hydrocarbon readings but still show about 125 on a compression test? You've got worn valve guides, pard. (Oil is a hydrocarbon too.)

Since the valves don't show much wear, a lot of folks reuse them. Bad, bad idea. You can regrind & reuse the intake valves... mebbe once. But you should always replace the exhaust valves. That's because the exhaust-valve ‘wear' you really have to worry about has to do with metallurgy, not the dimensions. After thirty to fifty thousand miles of use your exhaust valves are liable to suffer metal fatigue and snap off just behind the head. Saving a few bucks by reusing the exhaust valves can cost you the price of a new engine. Some bargain, eh?

Juicy Rockers

Veedubs don't have a very good lubrication system. All the oil to the right-hand side of the engine gets there via that tiny little channel behind the #2 cam bearing. Everyone who has rebuilt more than a few veedubs has seen the galling on the underside of the rocker-arm shaft, inside the rocker arms themselves, and the wear marks on the washers & rocker-shaft towers. After a few dozen engines you learn to reverse the rocker shaft and swap it from left to right in an effort to equal out the wear. But about the third time you have a hair pin snap, you figure there's gotta be a better way and you start fooling with the lubrication system. Most guys raise the pressure by stretching the spring. That helped a little. But if you modified those war-surplus Wisconsin jugs to fit your 36hp engine, with your home-made dual-carb manifold and three pound flywheel, soz you could keep up with the Model A's all the other kids were running, you quickly discovered that more power meant more heat and more heat made the lack of adequate lubrication even worse.

(Work with me here. I'm talking 1956.)

Turns out, there's a whole buncha things you can do to get more juice up to your rockers. And juicy rockers don't gall. Nor does the hair-pin snap. And all that extra juice out in the valve gallery picks ups a shit-load of extra heat and that means your dinky 7mm valves stop wearing at such a furious rate. (Ed.Note: Early valves had 7mm stems.)

So you do all that stuff. And end up with a reliable little screamer that will flat eat a Speedster and life is good. Except for that huge cloud of white smoke that seems to follow wherever you go.

Speedster For Lunch?

The basic VW engine design dates from the early 1930's. Unfortunately, it stayed that way for the next fifty years :-) But not in the hands of American hot-rodders. From the mid-1950's there has been a steady flow of race-proven modifications applied to the VW engine. The most effective modifications are surprisingly simple and while they are common knowledge to all competent engine builders, the odds are you've probably never heard of them. They've never appeared in any of the magazines that I know of, probably because there's nothing to sell - the mods are made when you build the engine. Nor were they applied to street machines because the lack of effective valve stem seals guaranteed you'd flunk your smog check.

That was then.

Nowadays effective valve stem seals are commonly available. They don't happen to fit stock Type I valve guides but in the file of illustrations (linked below) I've shown you a couple of ways around that.

Valve Stem Seals

Valve Stem SealsIf the engine is running, there's a vacuum in the intake manifold. Wide open throttle, the vacuum isn't very much, slow idle it's a bunch but the key point is that it's always there. And when you got a vacuum on one end of your valve guides and atmospheric pressure on the other, there's going to be some amount of flow between them. The only way to prevent that flow from carrying oil vapor from he valve gallery into the combustion chamber is to install a seal on the valve stem.

Volkswagen began using valve stem seals starting with, I think, the 1964 model year (i.e., engines produced after August of 1963). That's those little black donuts you find stuck to the screen when you do an oil change. That's right; those niffty ‘seals' get baked as hard as a bride's biscuits, break, and end up in the sump. Which is sorta sad because if you did have good seals on your valve stems you wouldn't use so much oil and you'd probably have no trouble passing your smog. (The engine in my 1965 bus measured 71ppm HC out of an allowed 670ppm. Yeah, I know - it's so old it's exempt. I have it checked now and then just to show off :-)

I've got good valve stem seals on all of my air cooled VW engines. You gotta do it yourself but I figure it's worth the effort, especially since I do a few others things as well.

Valve Guides

If you order valve guides for an air cooled VW from five different sources, you're liable to get five different sizes. If you've ordered STD the body of the valve guide should be about 12mm in diameter, have an overall length of 61mm and a bore just a tad over 8mm. But all of their other dimensions are liable to vary from one manufacturer to another. Fer instance, valve guides come in standard plus two over-sizes, the largest having an OD of 13.25mm. STD guides, with OD of about .4577, you can make out of half-inch diameter bar stock but second-oversize, some outfits use 14mm, some use 15mm, others use 9/16... you never know what you're going to get. Which is no sweat, since they'll still fit. What's different is the maximum OD of the rim around the top of the guide. And that becomes significant if you want to use valve stem seals, because the seal plugs on to the top the valve guide.

A good (i.e., modern) valve stem seal sockets down onto the guide with a fit so tight you have to drive them on and need a special pry-bar to get them off. (Actually, they never come off once they're driven on. When the guide becomes worn you throw the seal away when you remove the old guide.) The problem here is that since VW never used a good valve stem seal on its air cooled engines, there isn't any spec for the height & diameter of the rim on the upper end of the Type I valve guide. If the guide is made from 9/16 stock (not uncommon for the larger over-size), that's what you get for the top-end of the guide; ditto if it's made from half-inch stock.

Whatcha gotta do is measure the guides then find a valve stem seal that will fit that particular diameter. At least, that's the theory :-) What you'll probably end up doing is using VW Rabbit guides for your intake valves... and VW Rabbit valve stem seals. Which ain't a very good idea, even though lotsa folks do it that way. (They say it gives them better flow.) Rabbit guides are about an inch shorter than Type I guides. That leaves a lot of the valve stem exposed and that can cause the valve stem to collect crud and stick open. Not a major problem for a car engine although it's a pain in the ass since you have to pull the head to clean things up. About the worst thing that can happen is to use the shorter Rabbit guides for both intake & exhaust. Don't work. The Rabbit guides are shorter because the engine is water-cooled. Air-cooled, you need the longer Type I guide to provide the required heat-transfer surface. Use the shorter Rabbit guide, the exhaust valve eats it in a matter of miles. Classic shade-tree repair, though... guarantees you'll break down just far enough away so as to become someone else's problem :-)

I don't use Rabbit guides.

But I do use Rabbit seals. And Toyota seals, some of the time.

What I do is buy a batch of valve guides. If they're fat, which is usually the case with oversize guides, I machine the top of the guide to accept the Toyota valve stem seal, which needs an OD of at least .525 inches for a good fit. The Toyota seal is fairly long - about three tenths of an inch - so I may need to grind off some of the skirt.

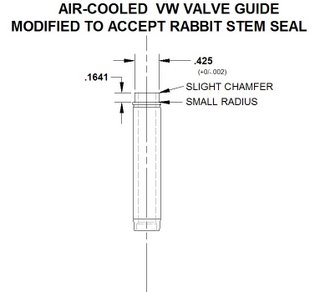

Most STD valve guides are made from 13mm (.512) or half-inch stock, depending on what country they come from. You can fatten up a 13mm guide to accept a Toyota seal by knurling the upper lip of the guide but in most cases you'll get a better fit if you turn down the upper lip to about .425. That will allow it to accept the Rabbit seal.

How do you machine it? In a lathe. One of those little hobby-lathes will do. In fact, if you got kids around the shop modifying valve guides using a baby lathe is one way to introduce them to the arts of Tubal Cain.

The Cost of it All?

Durt cheep.

Figure about a buck each for the seals, one to three bucks for the guides. Shop around. A couple of years ago I bought a batch of 100 Type I valve guides from a VW engine rebuilder who was going out of business. Two bits each. J.C.Whitney occasionally offers VW engine parts on sale; I've bought guides from them for as little as a buck each.

Ordered via the Internet I think I paid eighty-eight cents for Rabbit seals and two thirty-five for Type I valve guides. For comparison, a local VW dealer wanted over seven dollars for the seal and nearly twenty bucks for a single valve guide. (Apparently no one at VOA has ever heard of Adam Smith. :-)

Are Valve Stem Seals Worth the Trouble?

That's up to you to decide. The lubrication mods provide a significant improvement to the Type I VW engine but increasing the amount of oil to the valve gallery guarantees a dramatic increase in oil consumption... unless you install valve stem seals.

I like dull engines; engines I don't have to worry about nor tinker with. But at the same time I want my engines to be as fuel-efficient as possible, more powerful than the other guys and to last five times as long. The lubrication modes address those issues but the mods are impractical for street use without effective valve stem seals. So for me, yeah, it's worth it. Your mileage may vary :-)

Can I Do It?

Of course you can! Real engine-builders have been doing it that way since the early sixties. Just because you haven't seen it the magazines doesn't mean you won't find it at the finish line. You'll have to find someone with a lathe to modify the new guides and you'll need some tools & a simple wooden fixture to hold the head while drilling out the old guides, but that's what mechanic's do. An you are the Mechanic-in-Charge.

-Bob Hoover

-Feb 2003

No comments:

Post a Comment